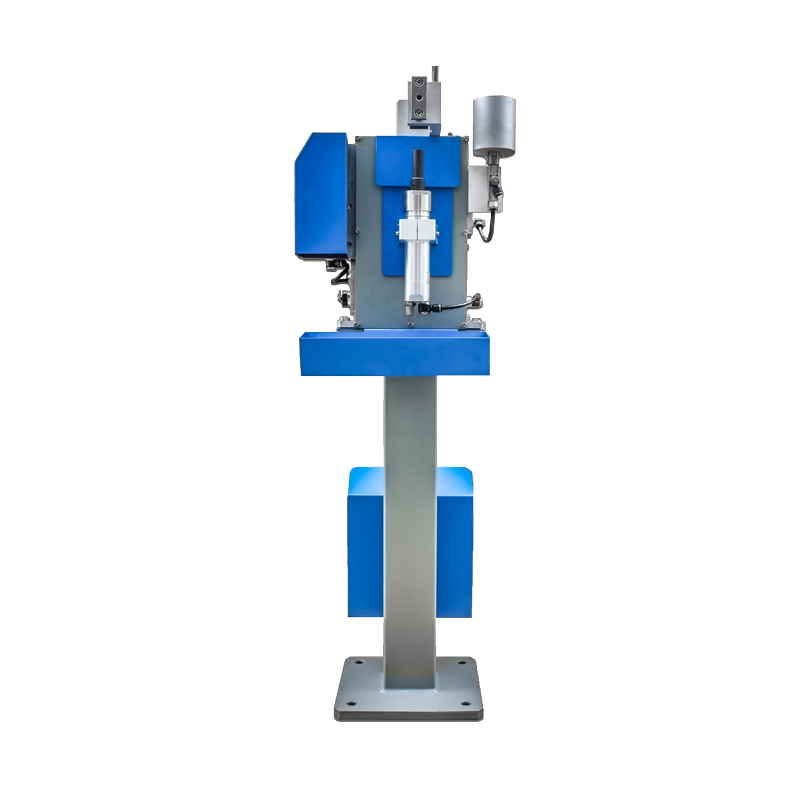

KELEI Thunderbolt Torch Cleaner

Introduction

Thunderbolt is a comprehensive and automatic torch maintenance platform. It’s very simple to assemble, plug and play. The compact and reliable platform integrates three function modules which help scale down the size and lowers the requirements for maintenance.

As the auxiliary equipment of the welding robot, the torch cleaner plays an important role in the welding automation process. the torch cleaner can automatically clean the spatter on the robot welding torch, ensuring that the gas channel is unimpeded, to better protect the welding area. The cleaner can perform a comprehensive cleaning process of torch cleaning, oil injection and wire shearing. The integrated process further improves the automation efficiency, and ensures the cleanliness of the welding torch.

Specification

Weight: ≈19KG

Working Environment: +5°C bis+50°C

Air consumption Approx. 380I/min

Air Motor

Lubricated: 650 rpm

Standard (unlubricated): 550 rpm

Start Connector module: G1/4 Compressed air output

Inner width: min 6mm

Nominal pressure: 6bar

Working pressure: 6-8bar

Control: I/O

DC Control Voltage: 24V

Required Power: 4.5W

D Working Voltage: 10-30V

MRL(Maximum Residue Limit): VSS<10%

Max Current: 200mA

Current Consumption: 4mA(24V)

Voltage Drop: 1.2V(200mA)

Anti-splash device

Liquid Container Capacity: 1L

Wire Cutter

Cutting Rate (under 6bar) -Solid Core

Flux Core: 3.2mm

Cutting Time: 0.5s

Support

Manual, Accessories

Products and Applications

Details