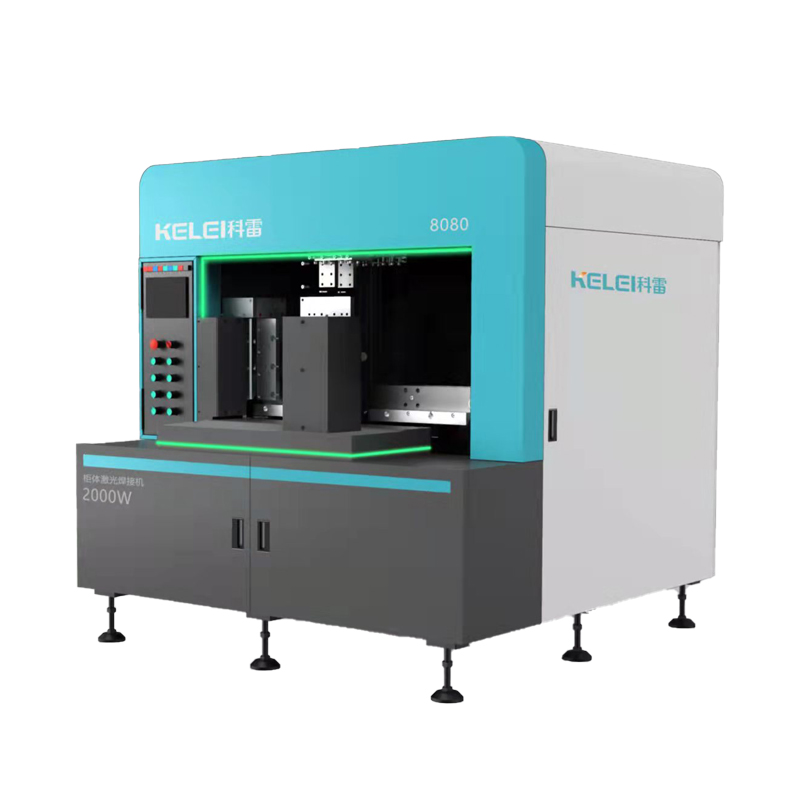

KELEI Box Welding Station

Introduction

Why should we choose laser for welding?

Laser welding uses the laser as the heat source for welding. As the laser radiation heated up the working piece, materials melted and joined to complete the weld. Laser welding has the benefits of precision, small heated zone, low deformation, and high efficiency. Laser welding is the achievement of the developing technology of laser and control systems, which also evolved into an advanced technique for metal processing.

The box welding station can achieve efficient box welding with a 2000W laser output and a fully automatic welding process, which is ideal for welding electrical cabinets, metal boxes etc.

Video

Box welding station is simple, low-maintaining, and precise. It requires minimal training for workers to operate. The fixtures are well thought to accelerate the welding speed. For thin plate welding, especially at right angles, the welding station can effectively control the deformation caused by heat and thus produce smooth welding, and neat corners, without welding stains.

Specification

Model, Max Output Power: MNJ-2000w

Application: metal boxes, electrical cabinets, standardised components

Industries Applied: metal processing, sheet metal, manufacturing, electricity

Central Wavelength: 1070-1090nm

Max Output Power: 2000w

Max Pulse Energy: 10mJ

Max Welding Width: ≤800mm (adjustable)

Max Modulation Frequency: 100KHZ

Input Power: AC220V50-60Hz±10%

Working Temperature: +5℃—+40℃

Warranty: one year for the product and two years for the laser diode