KELEI Aeolus Handheld Laser Cleaning Machine

Introduction

Aeolus cleaning system integrates a 1000W laser diode, rigid galvanometer system, and an ergonomic compact handheld cleaning head. Aeolus produces outperforming cleaning results appreciate to its highly-adjustable user parameters, LD’s reliability and high laser pulse power. The unique handheld galvanometer cleaning head design allows users to agilely adjust the laser output angles in order to process complex surfaces. The advanced control system and delicate synchronization technology boost the processing speed of the cleaner and unleash the potential of removing the undesired coating and paints on the workpiece.

The handheld laser cleaning machine is convenient and flexible to operate. Two models are provided with laser power 1500W/2000W. Laser cleaning is an efficient and environment-friendly technology, which does not require any chemicals or cleaning fluids when compared to chemical cleaning. Compared with mechanical cleaning, laser cleaning causes no grinding nor pressure to the workpiece, and it uses no consumables. The laser can transmit within the flexible optical fibre to make cleaning in hard-reaching positions a lot easier, nuclear plant pipeline cleaning for example. Thus, laser cleaning could be applied to rust removal, paint removal, sludge removal, and wafer surface treatment. The laser can remove targeted particles at the nanometer level, therefore this technology has been applied internationally in various scenarios including mould cleaning and jet fighter coating cleaning.

Specification

Model: Output power:

LS10001000w

LS15001500w

Application: cleaning or removing paints, rusts and coats on metal surfaces

Applied Industries: metal processing, sheet metal, manufacturing, machinery

Central Wavelength: 1070-1090nm

Max Output: 2000w

Max Pulse Energy: 10mJ

Pulse Width (adjustable): 70-500

Modulation Frequency: 100KHZ

Input Power: AC220V50-60Hz±10%

Working Temperature: +5℃—+40℃

Warranty: 1 year for the welder and 2 years for the laser diode. Lens, fibre, and other consumables are not included.

Products and Applications

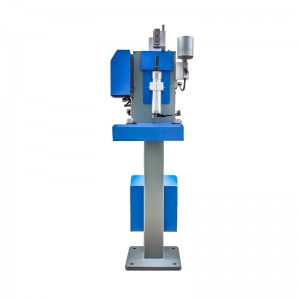

The No.100 Cleaner Assembled